TQC Ltd, Hooton Street,

|

|

Contract Leak Testing Service for Production Parts Do you need a part leak testing? TQC is able to offer contract leak testing services for production parts where the investment in instrumentation is not justifiable. TQC do not carry out site testing of large tanks and pipe work. Our resourceful engineering staff can develop and write test specifications and procedures to cover any critical testing requirement. The service is used by Clients who:

Typical Examples are:

TQC standard equipment includes a full set of calibrated, traceable leak testing instrumentation (NIST, NAMAS) available for leak testing small quantity batches of parts. Our capability covers an extensive range of pressures from high vacuum to 6 bar. Typically, using air decay, leaks of 10 mm3.sec-1 can be found, using helium leaks down to 1x10-8 mbar.l.sec-1 can be identified. Higher proof test pressures of up to 1095 bar can be accommodated by special arrangement and review of safety. The techniques available are differential pressure air decay and helium tracer gas testing services. These techniques include helium spraying and helium sniffing to locate leaks. In simple terms, the sample parts need to be connected to a test instrument. TQC has equipment available for this including standard connectors and test chambers and the ability to manufacture sealing plates and bespoke sealing arrangements as required.

Where possible TQC will use standard reusable parts to make the test as economical as possible. Typically it takes a couple of weeks to assemble the parts and perform the first tests, this can be shorter if all the equipment is standard but a little longer where special parts have to be manufactured. Contact TQC via the details below about leak testing your parts.

Leak testing provides the following benefits:

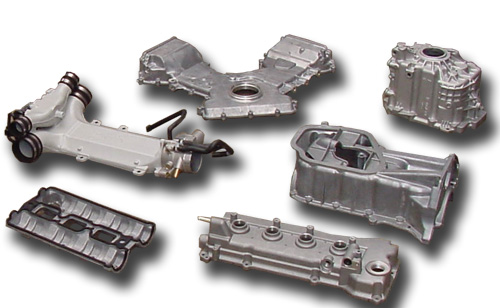

For further details of leak testing and leak test machines look at some of the other pages. As a taster, products succesfully leak tested over the past years include the following

If you have a current project that you are already looking at, or you are considering improvements to your production in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

||||||||||||||||||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

||||||||||||||||||||||||||||