|

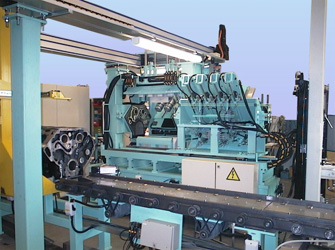

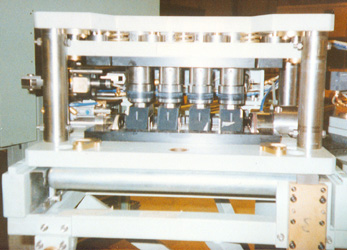

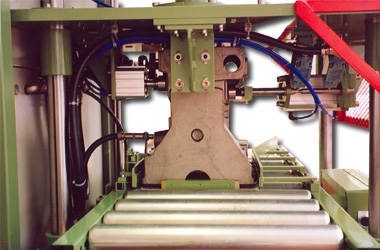

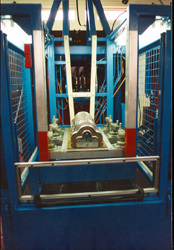

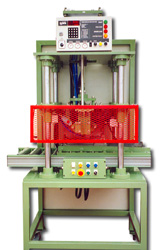

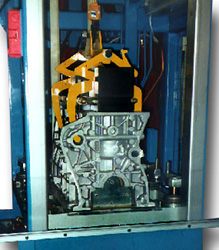

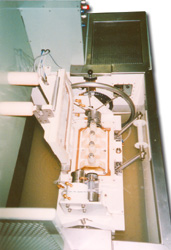

Leak Testing Sector Overview from TQC Leak Testing of Engine Blocks TQC have produced a number of leak test systems for a variety of automotive parts, this includes equipment for the testing of engine block castings. The machines supplied to date include manual and automated loading / unloading, multi cavity leak testing functions and system diagnostics. TQC incorporates standard concetps and customises the equipment to suit the components and test parameters. Examples of components tested include the Vauxhall V6 engine, Rover K Series, Jaguar, Scania etc. Features, Tests & Functions

Typical Leak Rates and Test Pressures for no-fluid leakage:

If you have a current project that you are already looking at, or you are considering improvements to your production in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

||||||||||||||||||||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

||||||||||||||||||||||||||||||