|

Leak

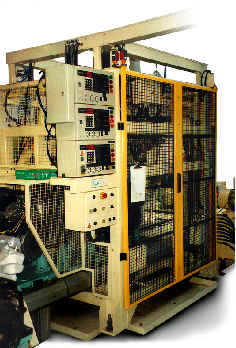

Test Application from TQC

V6

Engine Leak Test & Locate System

- Simultaneous leak testing of water and oil systems

- Internal leak testing of oil and water

cavities

- Automatic sealing of assembled engines

- Multiple leak test instruments

- Palletised conveyor system with individual

engine bar codes

- Tracer gas charging and purging console

for use with helium or hydrogen.

- Quick connect sealing plug.

- Hand held sniffer probe for leak area

location.

- Automatic reject conveyor loop with manual

leak location station.

- Office-based data management computer

(DMC) connected to the leak test system via a local area network

- The DMC allows selection and viewing

of historical test results and the ability to edit test limits.

A facility is provided to export data for processing by other

spreadsheet and database software.

- Programmable leak rates and test pressures

to suit different engine varients

Typical leak limits are:

- Water system: 10cc/min @ 1bar

- Oil system: 25cc/min @ 0.3bar

- Internal water to oil: 10cc/min @ 0.7bar

differential

Throughput: One 2.5 or 3.0 litre engine

every 50 seconds.

|

|

|

|

| V6

Engine Leak Test Facility |

If you have a current project that you are

already looking at, or you are considering improvements to your

production in the near future, call us and we will be happy to offer

our professional advice & visit you at your site.

|