|

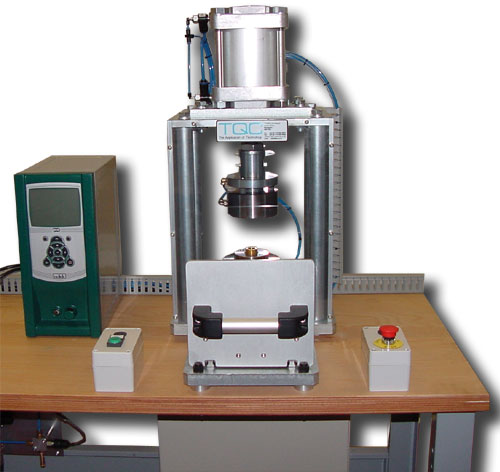

Leak Test Application from TQC High Pressure Audit Leak Test & Data Logging System Series 30 Based System The system shown is a quality control audit leak test facility with data logging for a brass product. There is a range of product sizes and shapes that are tested using interchangeable tooling inserts that interface with a common nest. The product is loaded into a drawer style fixture and moved into the test area manually, the leak test is fully automatic. The leak test uses high pressure nitrogen inside the product with the leak test instrument using a vacuum chamber around the part and detecting pressure rise in the chamber outside the component. To ensure that the instrument is not damaged by a grossly leaking part an initial low pressure test is performed, the part must past this test before the high pressure test is carried out. The test results are fed back into a PC for analysis with batch data, part number, die number and other parameters logged

System Features:

If you have a current project that you are already looking at, or you are considering improvements to your production in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

|||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||