|

Leak Test Application from TQC Helium Leak Testing of Plastic Fuel Tanks TQC has specialised in the automatic helium leak testing of components for many years. Fuel tanks have previously been regarded as a leak testing problem - the volume is unstable and too large for air decay testing. Water dunk testing is operator dependent and causes longer term damage to the unpainted tank. Neither method will detect a fine vapour leak. Now proven by several installations, TQC is able to supply Fuel Tank Leak Testing using Helium. The system provides a fast reliable dry test with numerical leak results. The sensitivity is equivalent to a "dunk tank bubble" once in several days. Connections to the tank are made automatically, the system is self-monitoring and the operator may be unskilled. The system is suitable for leak testing metal or plastic tanks.

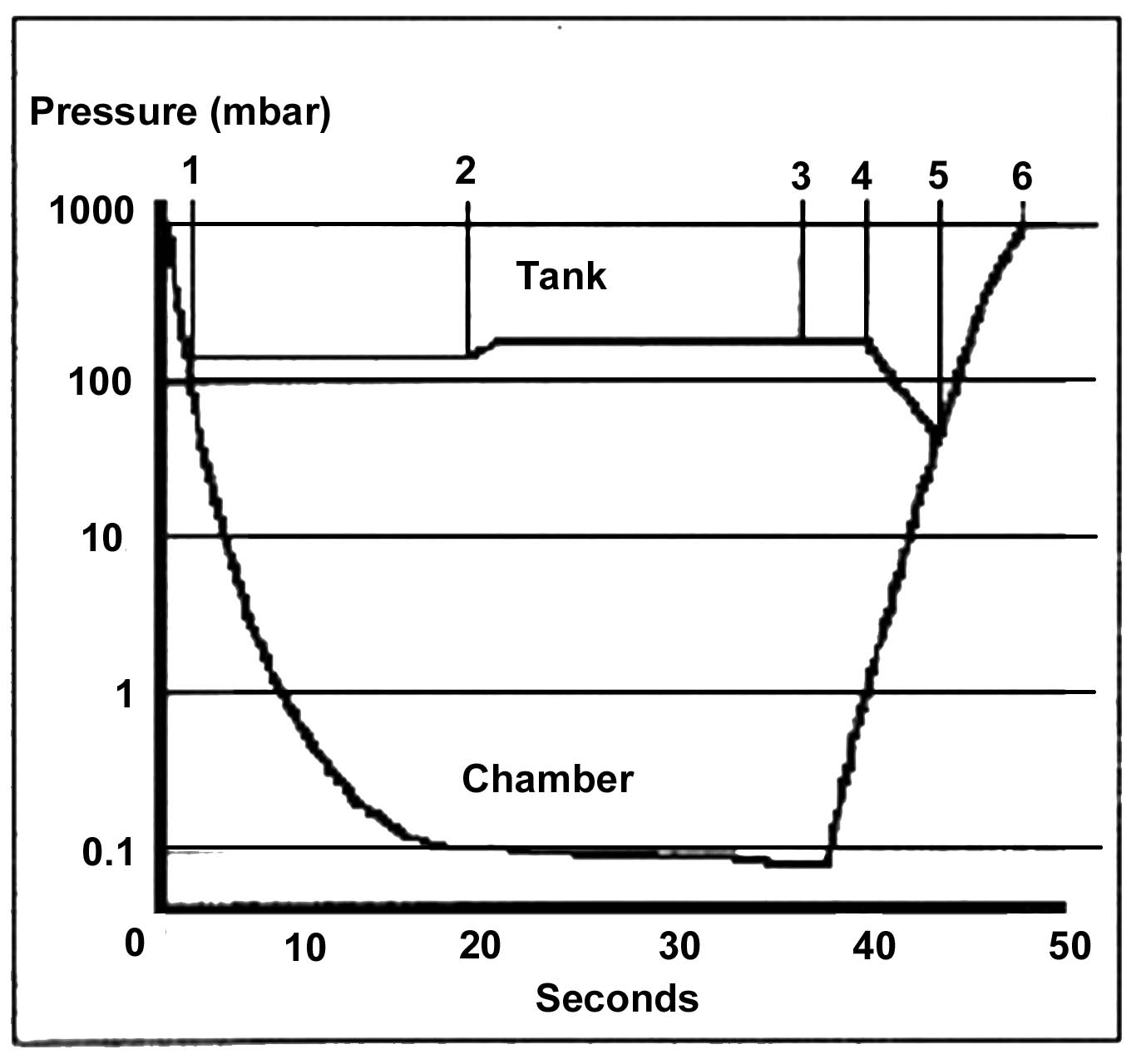

Typical specification for a 75 litre plastic fuel tank is:

System Description:

Vehicle Fuel Systems Legislation: Total vehicle and component assemblies are subject to a variety of fuel loss legislation requirements. Both US and EC evaporative emmissions requirements are the subject of continued revision and it is advised that the current USA Californian certification standard be adopted as the basis for vehicle component and assembly production acceptance. If you have a current project that you are already looking at, or you are considering improvements to your production in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

|||||||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||||||||||