|

Leak

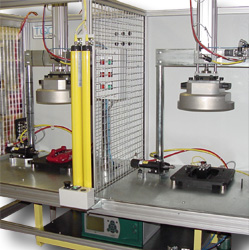

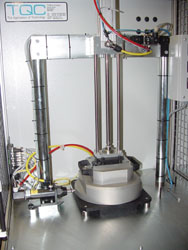

Test Application from TQC Automotive Brake Part Flow & Leak Testing - Series 40 Based System TQC have recently developed an innovative system for the automatic testing of high specification brake parts. The operator manually loads a part into the machine and connects the test line to do it. Firstly, an air flow test is performed to check for blockage. If successful, the part is automatically shrouded in a close fitting test chamber and 3 successive leak tests are performed using a differential leak test instrument as follows - 1. Intermediate pressure leak test (including piston

movement check) Good parts are pass stamped on completion.

If you have any leak or flow testing requirements a cost effective solution can be developed using standard equipment and bespoke elements as required. If you are currently considering any type of test application contact TQC to discuss your requirements |

|||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||||||