|

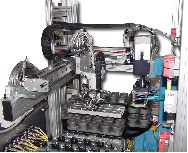

Leak Test Application from TQC High Speed Leak Testing of Plastic Vials for the Medical Industry TQC have developed a high speed, indexing rotary table based, leak test machine for handling and testing medical vials at 70 per minute. The system incorporates multi-channel leak test instruments, 10 banks of test modules and 2 display panels, these allow the plastic parts to be tested 10 at a time. The machine is fully automatic and utilises step feeders for accepting bulk, random product from a stillage, these two feeders transfer parts to an infeed mechanism to orientate and feed the parts in a 5 x 2 matrix. The indexing table has 4 positions, one for loading the parts, one for testing, one for unloading and a final empty station. The unload system incorporates dedicated tooling to allow the parts to be placed into pass, gross leak fail or fine leak fail bins. A fail safe system is included to ensure that there is no cross contamination of pass and fail parts. The system is PLC controlled and interfaces to a PC for data logging.

The unit incorporates :

If you have a current complex leak test or high speed leak test project that you are already looking at, or may require a leak test solution in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

|||||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||||||||