|

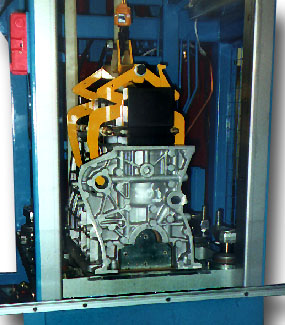

Leak Test Application from TQC Water Submersal Leak Detection & Leak Location (Otherwise known as a Leak Test Dunk Tank) Water submersal or dunk tanks are a widely used method for location of leaks in complex assemblies and products with air bubbles present around the leaking area. Most often, differential pressure or vacuum decay is used first to qualify a “tight” part. If the part leaks, simple decay of pressure does not show the leakage path. If a part fails the quantifiable test then one method of detecting the leak path is to submerge in water and look for bubbles. All of these examples use the technique of submerging the part in water. Some of these examples were used as the only leak test method. All of these examples had complex sealing requirements prior to the pressure being applied. Each of the systems locate the part or assembly into a fixture. The assembly is then clamped into place either by hand operated toggle clamps or automatically. Some sealing areas and the length of seal are considerable, requiring significant seal forces to both compress the seal and overcome the forces generated by the internal pressure. In all instances an operator makes a subjective visual check as to whether the part is good or bad. TQC specialise in leak testing and detection equipment and use off the shelf leak test instruments for air decay leak testing and for tracer gas testing.

If you have a current project that you are already looking at, or you are considering improvements to your production in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

|||||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||||||||