|

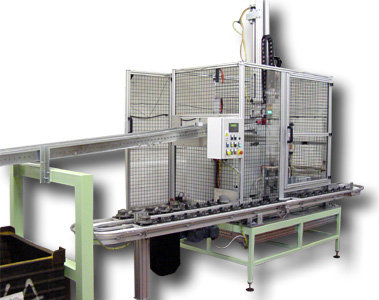

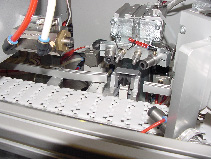

Leak Test Application from TQC Flow Testing of Turbocharger Housings The customer required a 100% production flow test for the water cavity with a turbocharger centre housing to ensure sufficient flow passes through. The flow test uses an air flow correlated to a minimum water flow value at a pressure drop of 0.1bar. The test checks for total or partial blockage of the water cooling cavity. This TQC system allows manual loading of parts into an infeed buffer and then automatic flow testing of the parts. At the test station the part is lifted clear of the platen, the open ports are sealed and air is used as the test medium. The air flow is measured and if sufficient flow is achieved, the part is marked as a pass. All parts are automatically unloaded by a 2-axis pick and place system, passed parts into one lane, failed parts into another. The empty platens are recirculated ready for manual re-loading.

Key Elements:

If you have a current project that you are already looking at, or you are considering improvements to your production in the near future, call us and we will be happy to offer our professional advice & visit you at your site. |

|||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||