|

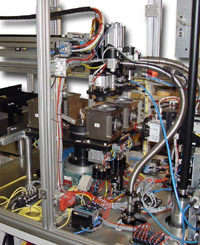

Leak Test Application from TQC High Speed Leak Testing of Welded Pipe Fittings Systems using Air & Helium as Test Mediums TQC have supplied a suite of 3 automatic leak testing machines that are conveyor fed. The first two machines were designed to 100% leak test numerous variants of welded metal T-pieces, elbows, reducers and adapters used in the water, gas and construction industries. The leak test specification meant that the parts needed to be water tight. The customer then asked TQC to develop a machine to meet the more stringent requirements of testing parts to ensure they are gas tight, and still meet the high production throughputs. TQC met these objectives by integrating helium leak testing technology into the same handling concept of the first two machines. The main features of each leak test machine are :

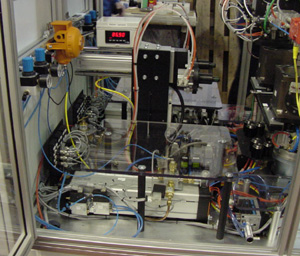

Handling System A twin gripper pick and place system was used to load parts from a conveyor pallet to the test fixture and then remove the parts after testing. Twin chamber test fixtures mounted on a rotating table were used to allow automated load and unload whilst meeting the high throughput. Air Test Medium Leak test instruments tested each component. Both internal high pressure and external vacuum was used to stress the part under test correctly and to provide a short cycle time leak test

Helium Test Medium The test process required the part to be evacuated, low pressure helium inserted for a gross leak test, then high pressure helium for a fine leak. On completion, the helium was removed from the part and the part stabilised with air. The system included monitoring of any leaking helium this allows fast testing and minimises helium loss by part leakage. Varian mass spectrometers have been integrated to monitor the helium gas, with a trigger point used to indicate a leaking part. The leak test threshold that was set by the customer was 1mm3/sec (1 x 10-6 mbar.l.sec-1). A helium reuse system was integrated into the test machine, this automatically monitored the gas quality and purged the system once the helium was below a set concentration. By including the recovery system typically 50 -100 parts (depending on internal volume) can be tested before the helium needs to be replaced.

If you are currently considering a high speed or complex leak test application, or production automation call us and we will be happy to offer our professional advice & visit you at your site. |

|||||||||||||||

|

Air Decay Leak Testing :: Helium Leak Testing :: Pressure Testing :: Fixture & Seal Design Specialists |

|||||||||||||||